Once upon a summer evening, I had a dream of walking around an art show. I was intimately familiar with all the work but recognized none of it. My heart was an ache and my mind was a blank. Within the course of the dream, I realized I was at a future exhibit of my own work. A retrospective perhaps? One room I entered was very dark with black walls. As I walked closer to the center of the room, I began to see figures of boys luminate. As I moved around the life size figures, their forms fell away as though they'd been painted on successive layers of glass. But there was no glass. The paint seemed to hang in the air. I proceeded to walk through the figures, between the layers, observing the artwork from all angles I could. The figures were made up of geometric patterns and a rainbow of colors up close. It was of a complexity I couldn't imagine contriving. And it was only when I stood back at one point in the room did the various shapes and patterns form a complete image. From any other angle, it was a beautiful offset abstraction. It was like nothing I'd ever seen. Like nothing I'd ever experienced. I was twenty years old and convinced I'd been given a glimpse of my future. Or if not my future, then it was a future I'd commit myself to manifesting. Within days of the dream, I used 3D modeling software to create a crude mock-up of the effect I witnessed.

Layered Resin Boxes

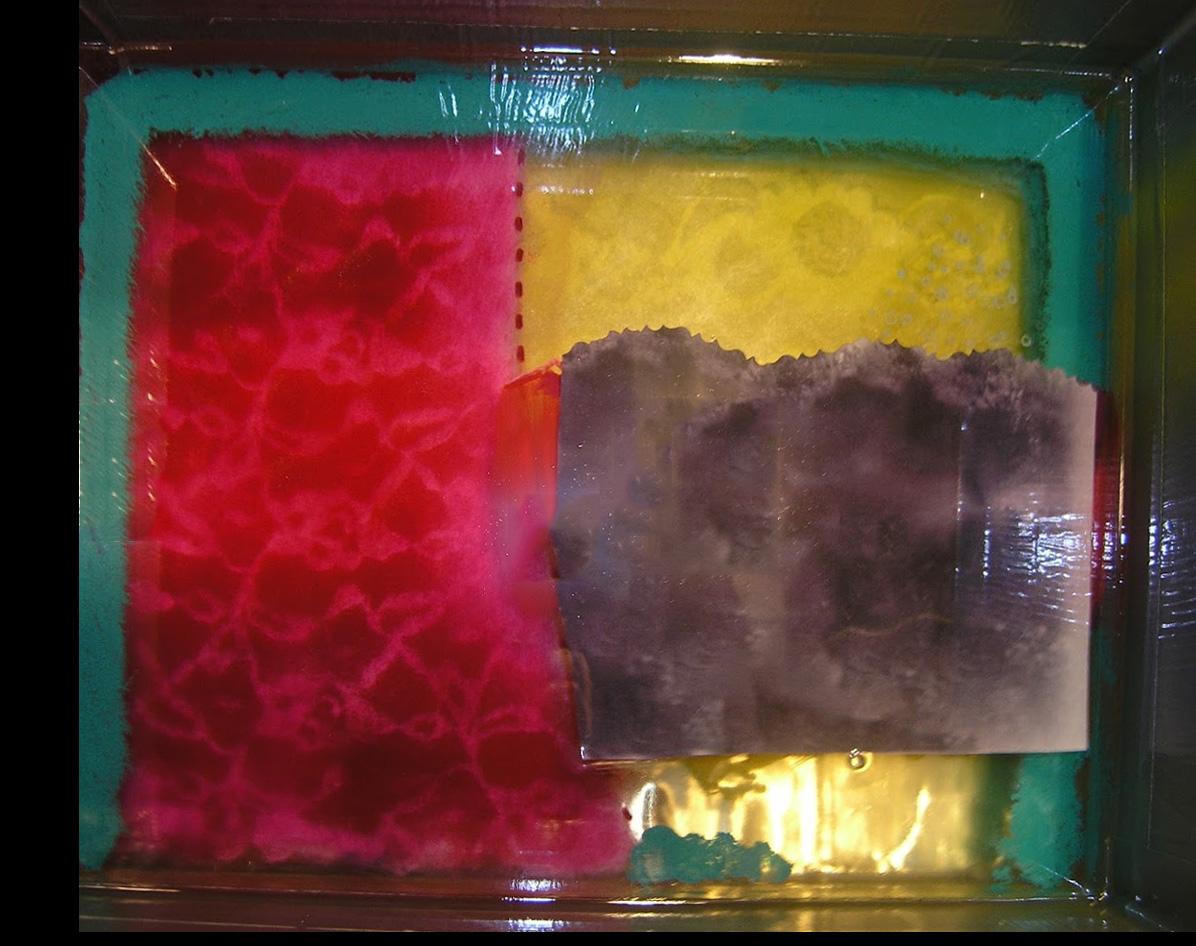

In 2002, I got the idea of using resin in my art after seeing a taxidermy specimen in a museum. The coyote's paw was submerged in what was supposed to be water-- and it had obviously been poured in successive layers in order to encapsulate tiny fish and debris at different levels. After consulting the internet for what taxidermists use to simulate water, I was off searching for a fine-art quality resin I could experiment with. I proceeded to create a series of these heavy, framed artworks. I had wanted to call them "Illumographs," for the illuminating effect of how light bounced around within the layers, but stood corrected by my gallerist, Ann Nathan, who dubbed them "Resin Boxes." This was my first foray since the 3D Modeling software into creating three dimensional layered paintings that were of actual substance; tiny prototypes of what I'd experienced in my dream.

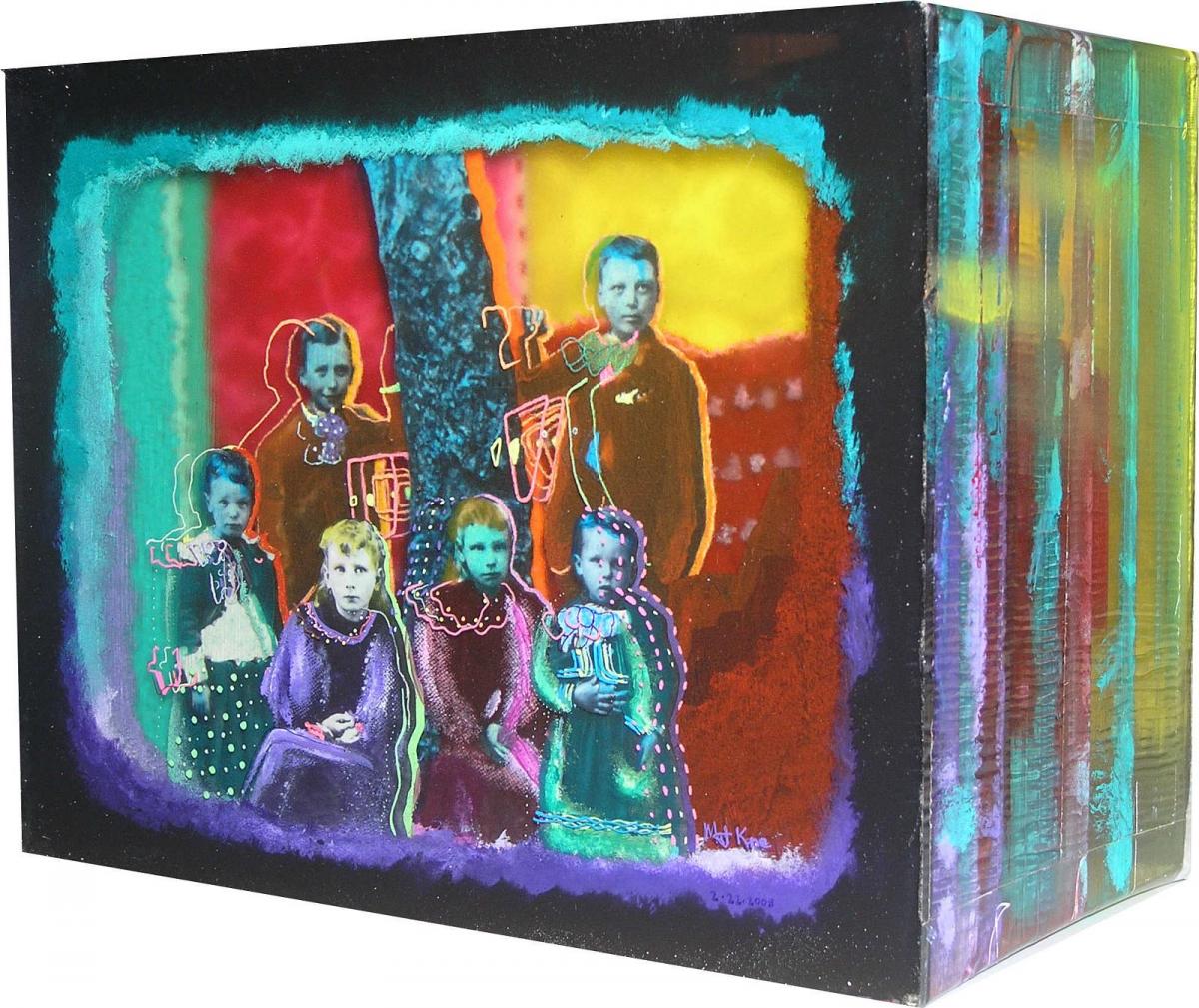

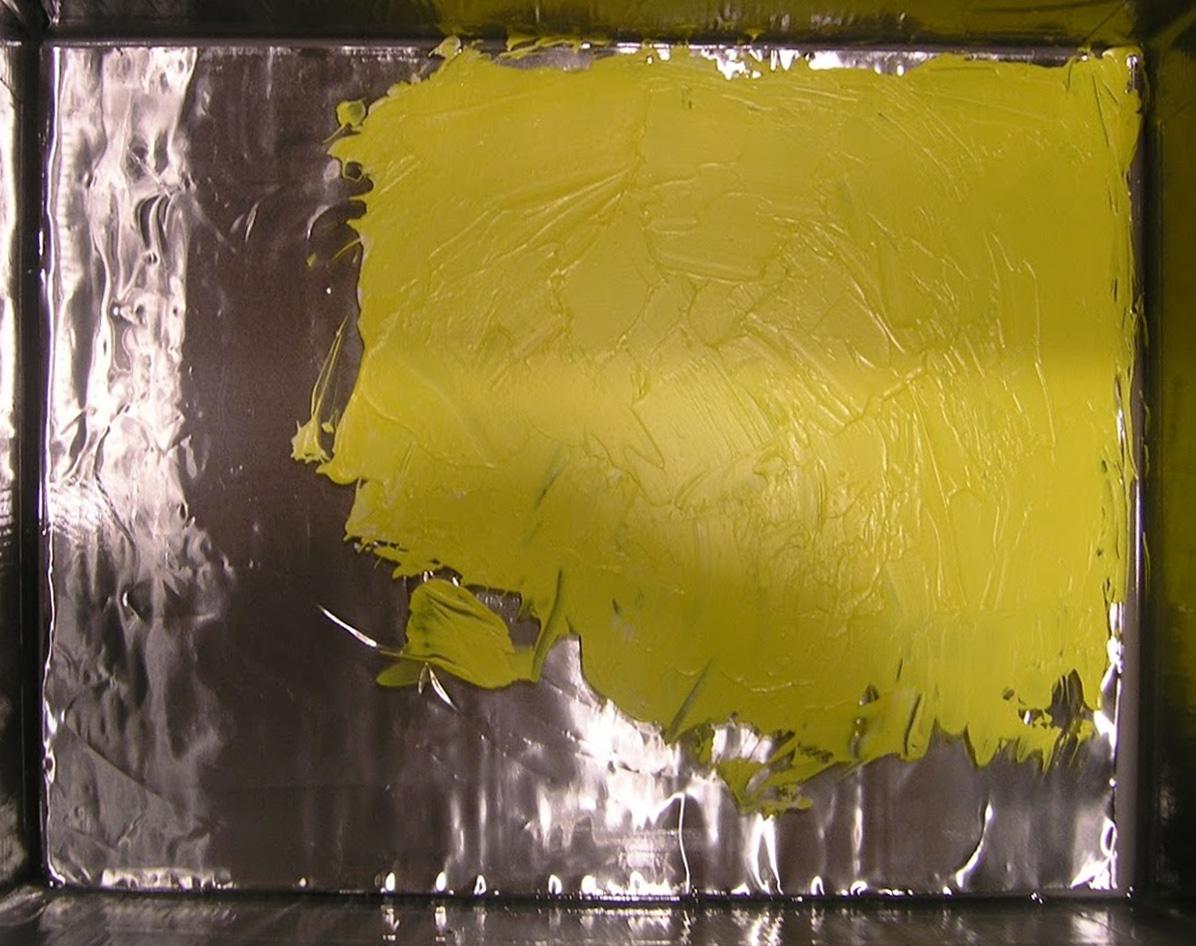

“Making of a layered Resin Box”

resin box by Matt Kane - “Making of a layered Resin Box”

In order to make a resin box, I'd pour a layer of resin within a duct tape sealed wood frame, let it cure, paint the surface, then pour another layer of resin. I'd repeat this dozens of times until a solid block emerged. Because each curing required 24-48 hours, it required a daily commitment to see the process through to the end. After pouring the resin, I'd use a heat gun to make the resin less viscous, and more prone to releasing air bubbles whipped up when the two parts of the resin were mixed. The curing occured within a rubber sealed vacuum chamber I invented. As air was sucked out from one valve, any air bubbles whipped into the mixture of resin came to the surface. Then, I'd open another valve which introduced an environment of pure carbon dioxide. This atmosphere mixture burst any air bubbles appearing on the surface of the resin. Because uncured resin is highly toxic to be breathed in or touch living cells, all of this had to happen while wearing a respirator and full chemical suit.

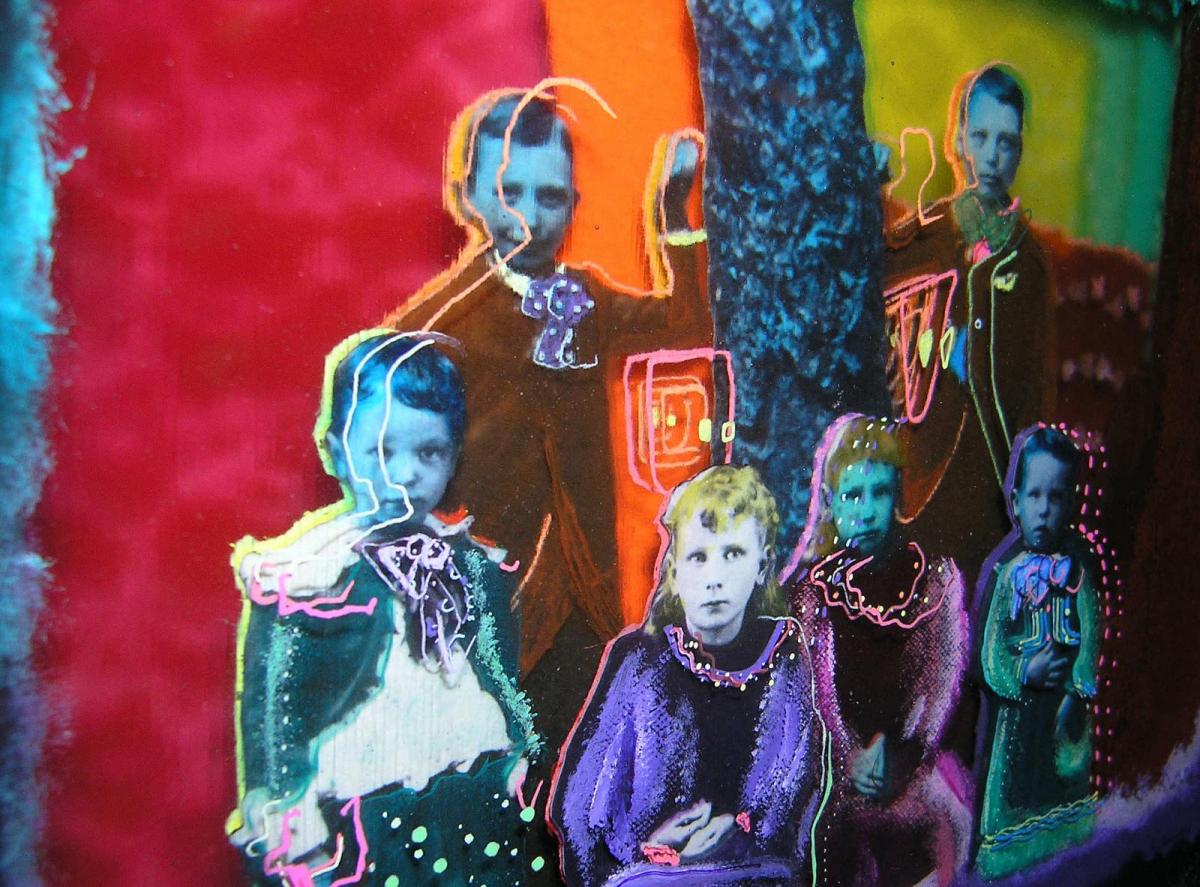

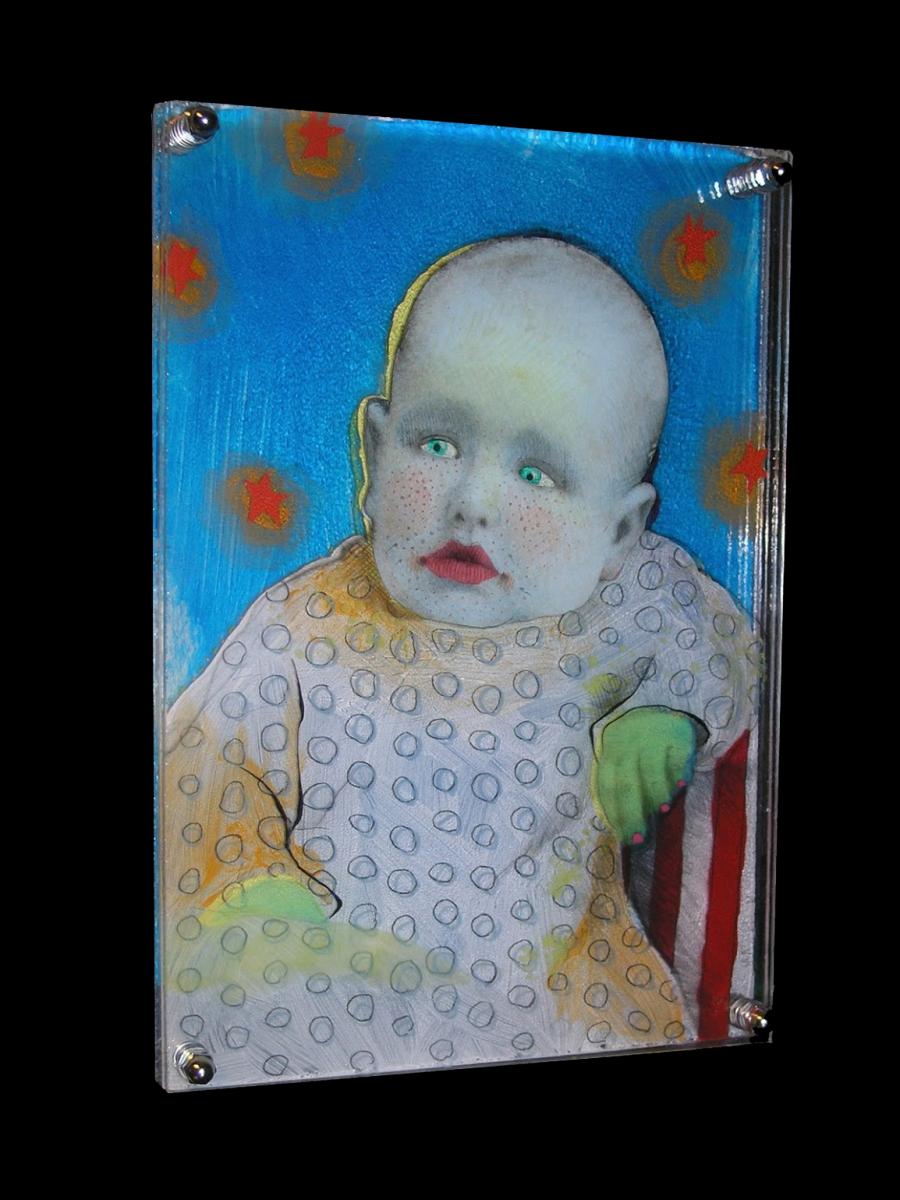

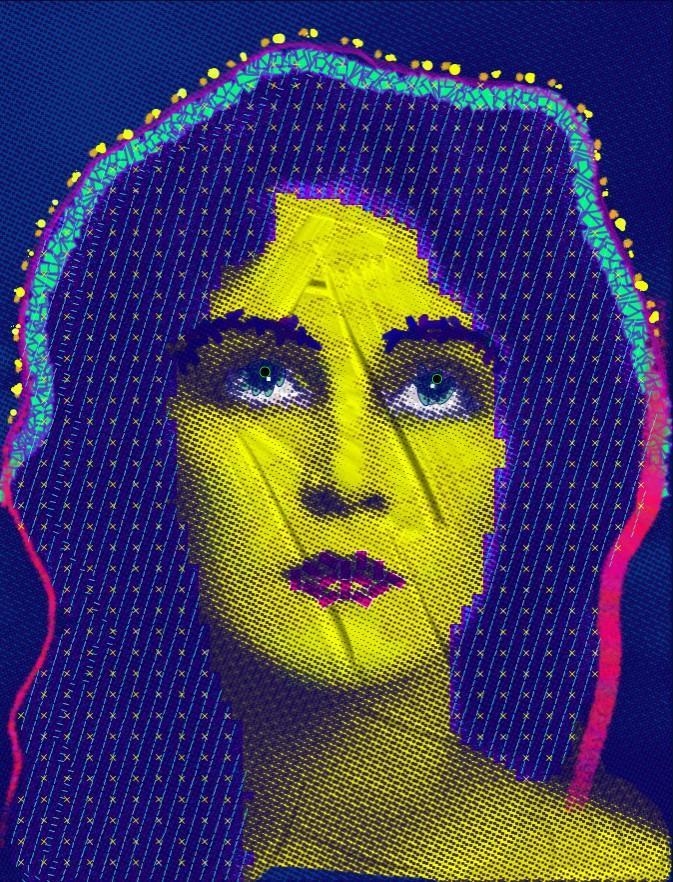

“Where I dream to lie in Circumstance”

resin box by Matt Kane - “Where I dream to lie in Circumstance”

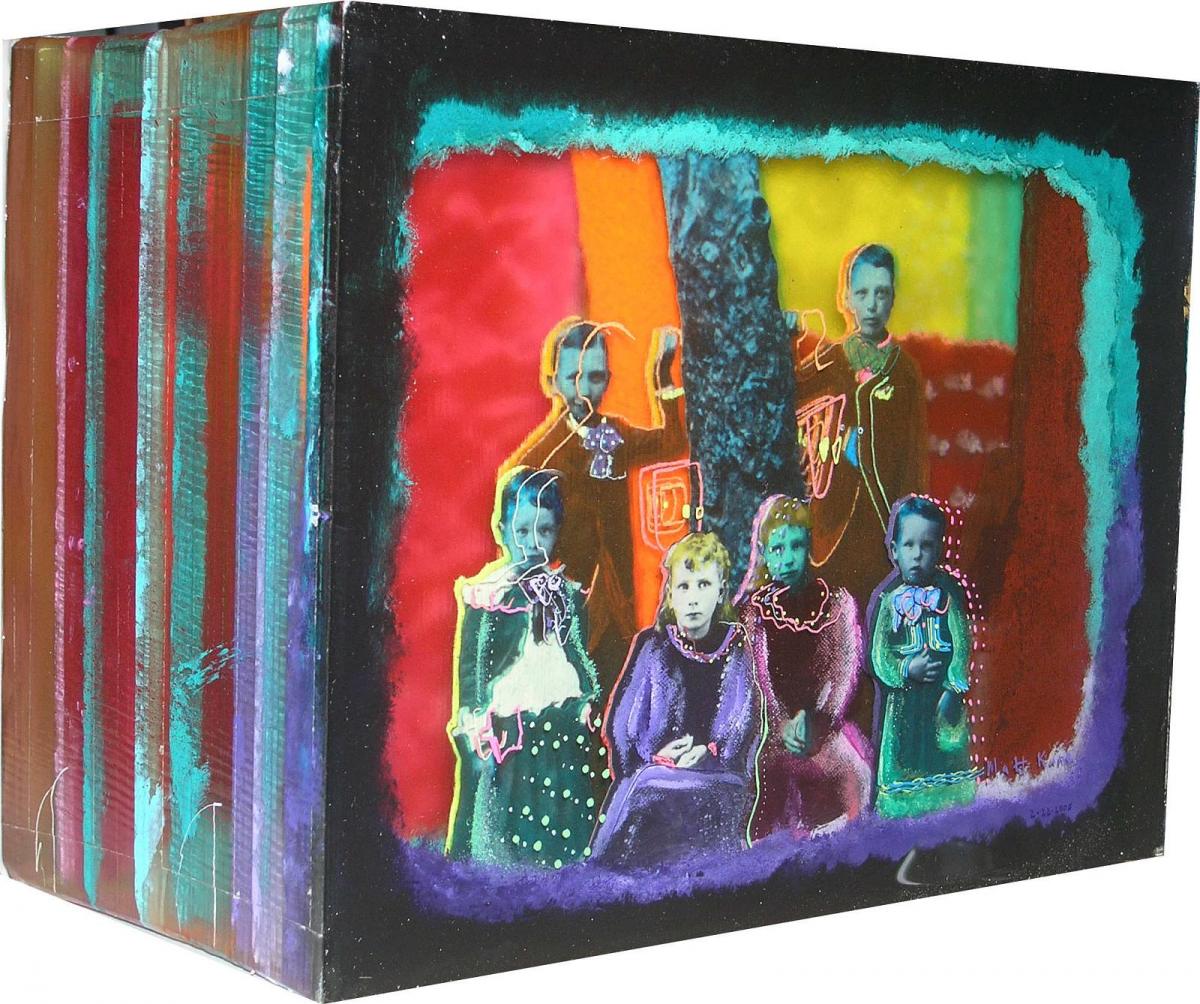

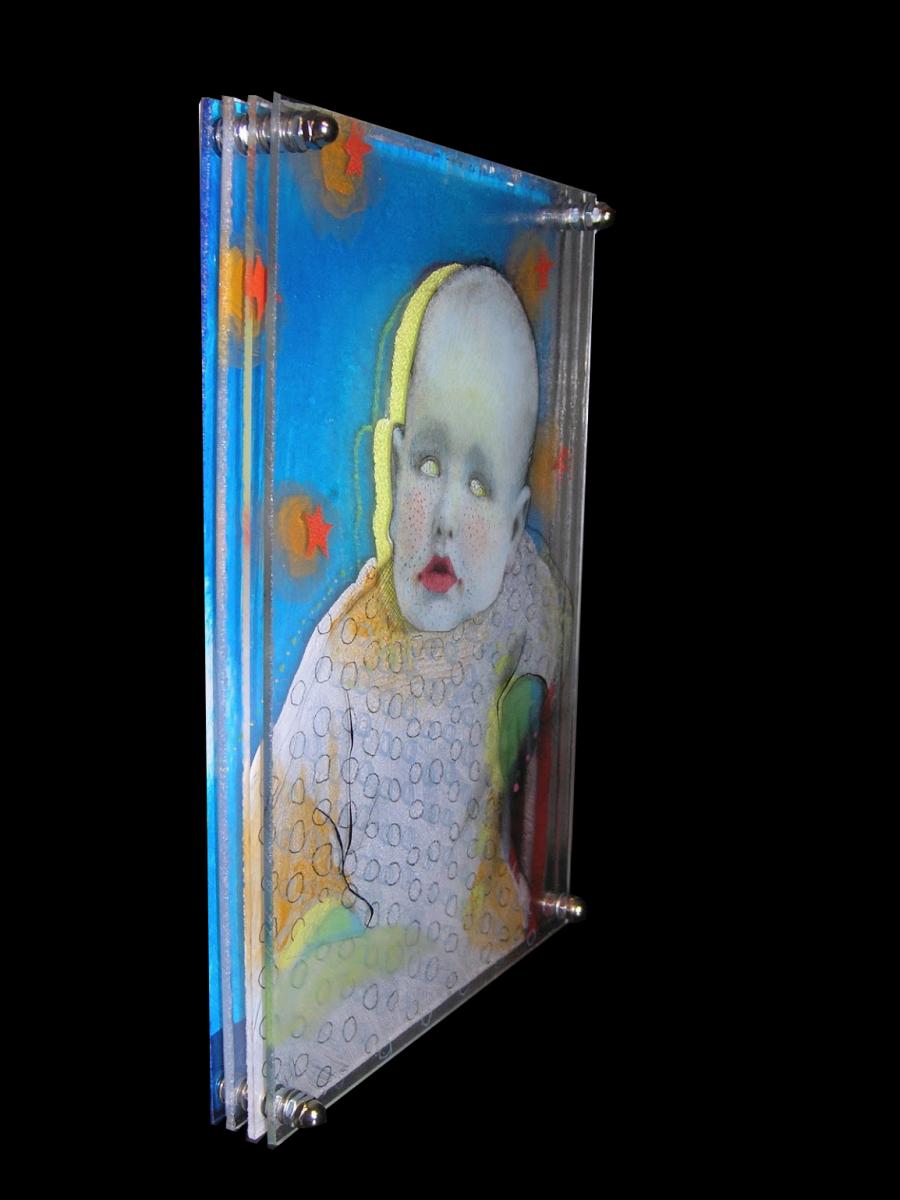

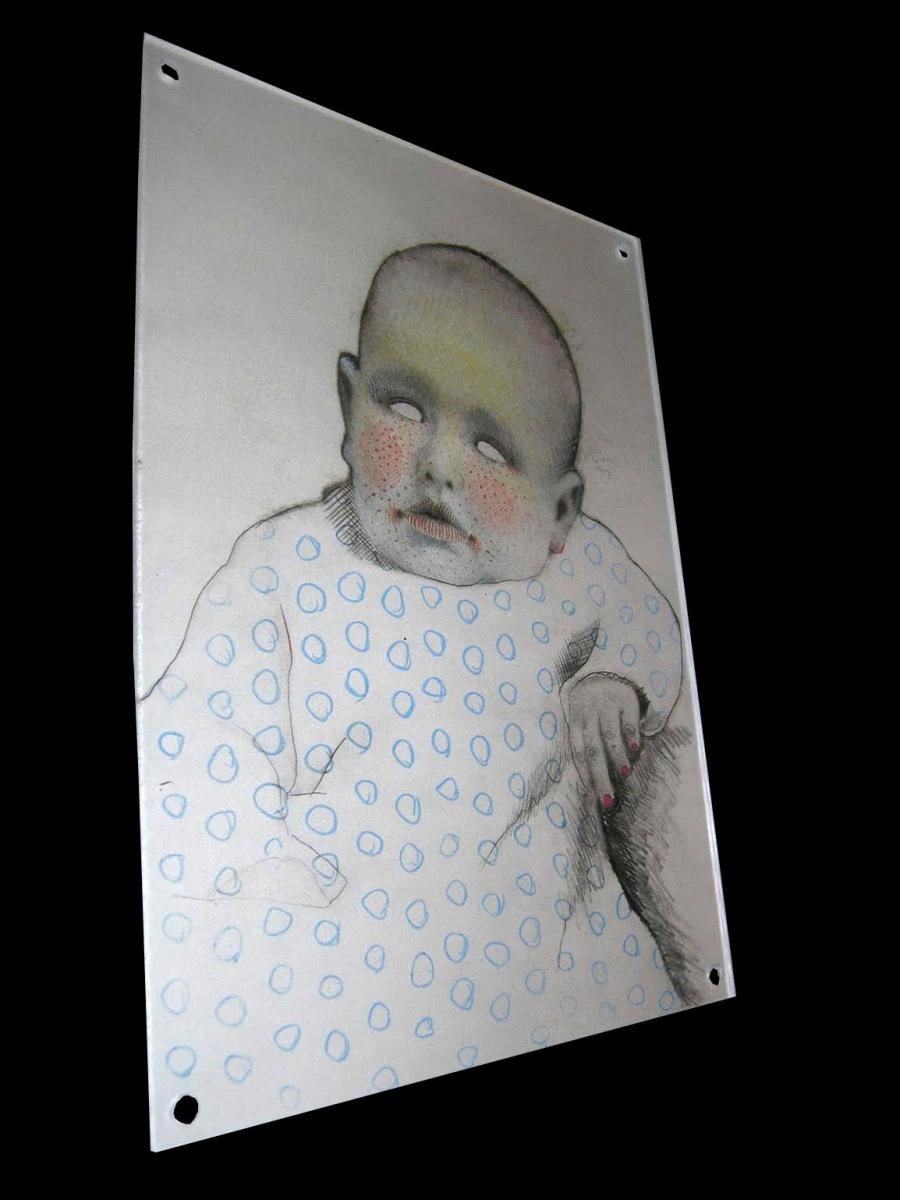

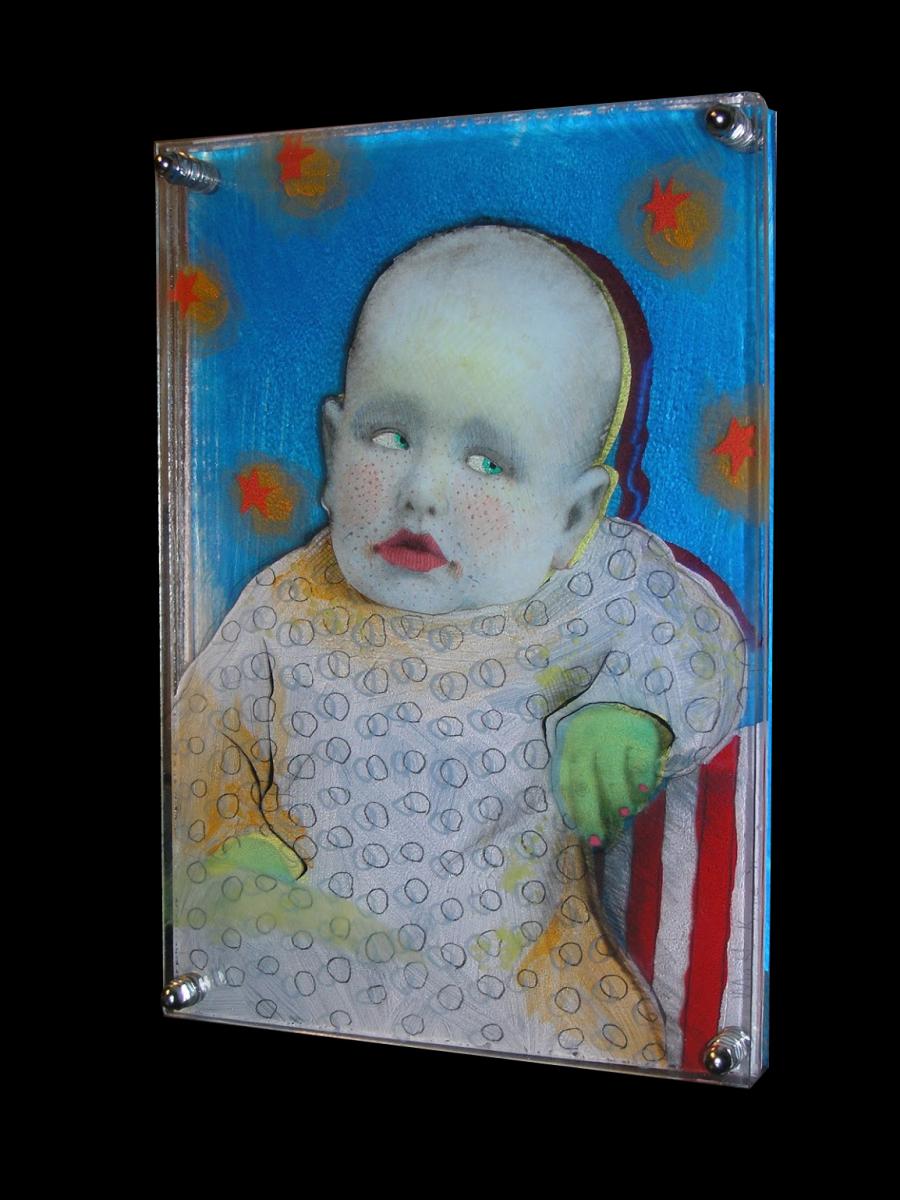

“Frameless Resin Box”

resin box by Matt Kane - “Frameless Resin Box”

By 2007, I'd perfected my resin box creation process, employeeing a more sophisticated vacuum chamber and pouring resin into homemade silicone molds. After unmolding, these were suitable for viewing from all directions, not requiring framing. The ability to view the artwork from all angles matched my inspirational dream. Few of these were made, though, before I decided for various reasons to discontinue using resin.

- Resin is dangerous and despite my precautions, I had health concerns associated with daily prolonged use of resin within a home studio.

- Resin boxes are extremely heavy-- even the small ones. Creating them at any scale simliiar to that of my dream was incompatible with my resources.

- Resin boxes are solid. In my dream, the figures were lifesize and I walked through them or at least between the layers.

I had to ask myself if my dream were a true vision of the future, then could the path forward be resin? Or should I move on and concern myself with materials that were more compatible with my vision? The answer was yes.

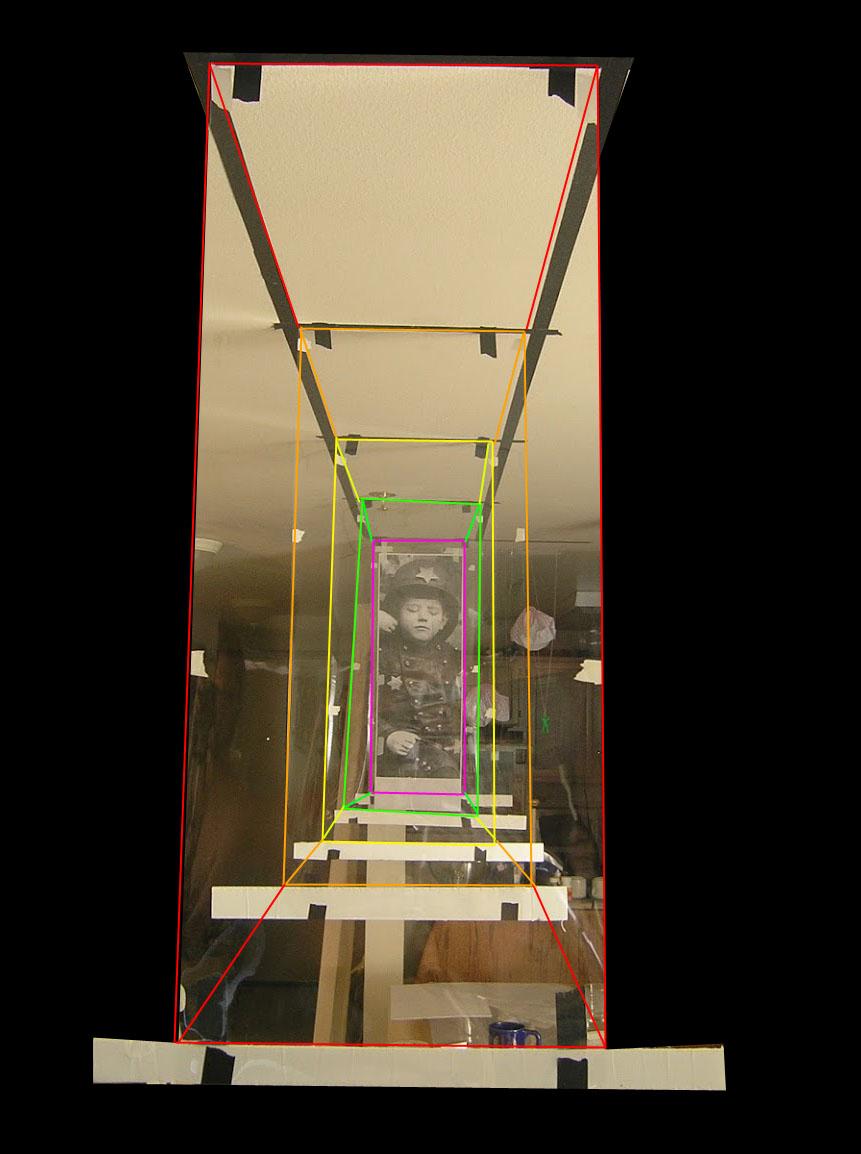

“Acetate Ceiling Hanging Proof of Concept Tests”

layered dimensional painting by Matt Kane - “Acetate Ceiling Hanging Proof of Concept Tests”

Between 2007 and 2012, I created within the dining area of my apartment a series of informal proof of concepts demonstrating image registration within a layered three-dimentional space. It was a foray into visual phenomenon I'd been visualizing many years, expanding from the small box size area of my resin boxes into the space of an entire room.

10 years since my first dream of envisioning layered dimensional paintings, I began working on sheets of plexiglass seriously in 2011. Truth be told, I'd first used plexiglass in some studio tests in 2004, but hadn't taken to them. My years of working on the smooth surface of resin provided great experience for moving to this material. Most of my innovations with materials translated. I consulted my reasoning for abandoning resin and compared them to plexiglass.

1. Plexiglass is already formed, no toxicity exists to endanger my health or home studio.

2. Plexiglass is lightweight and air takes up the space between layers, rather than heavy resin.

3. Plexiglass layered artwork allows me to at least move around the object and possibly between the layers.

It wasn't perfect, as I couldn't walk through the material as I had in my dream. But it seemed as good as any physical manifetation might be.

“Lyman”

layered glass painting by Matt Kane - “Lyman”

“2011 Parallax Javascript Software”

layered dimensional painting by Matt Kane - “2011 Parallax Javascript Software”